An innovative medical mask prototype made by students

As part of the M2 MAP 3D/2D course, from 2019 to 2020, two classes of students designed and produced an innovative medical mask in conjunction with two research structures at Lyon 1.

At the university, the years 2019 and 2020 were marked by the implementation of distance learning. The introduction of this system due to the health crisis required teachers and students to adapt in a very short time and the results of this new experience have yet to be assessed. However, this new form of teaching has given rise to pedagogical innovations. This is the case for the Master 2 course in Advanced 3D and 2D Materials and Processes (MAP 3D/2D) directed by Eliane Espuche (Professor at the University of Lyon 1) within the Chemistry and Materials Sciences field.

From 2019 to 2020, Vincent Salles, associate professor at the University of Lyon 1 and researcher at the Laboratory of Multimaterials and Interfaces (LMI) led a collaborative project with two successive classes of students in the M2 MAP 3D/2D course to realize an innovative mask for the filtration of fine particles and viruses, 3D printed and adaptable to the shape of the face.

A filtration membrane for SARS-Cov-2

In 2019, this associate professor and researcher is designing the new outline of his porous materials course to adapt it to the constraints of lockdown. Indeed, distance learning courses require more energy and focus from students, and practical work (PW) sessions are being eliminated.

"I wanted to do a distance learning course that was not lectured, involving the students and interesting them through a current topic. Porous materials are often related to filtration". Hence the idea of designing a membrane that would filter a virus like SARS-Cov-2.

The course on porous materials in the M2 MAP 3D/2D program deals with the various spinning techniques that exist in the industrial world, giving students the basis for this project. It is then up to them to think about the most suitable spinning technology to generate an efficient membrane filter against a particle as small as a virus.

Each student was then given a subject to deal with, taking into account various aspects: spinning technique, choice of bio-sourced materials compatible with the spinning technique, regulations, marketing standards, etc. "The objective was for the students to mobilize themselves to go and find information, to think and provide answers together to a problem for which I myself did not have the answers a priori," says Vincent Salles.

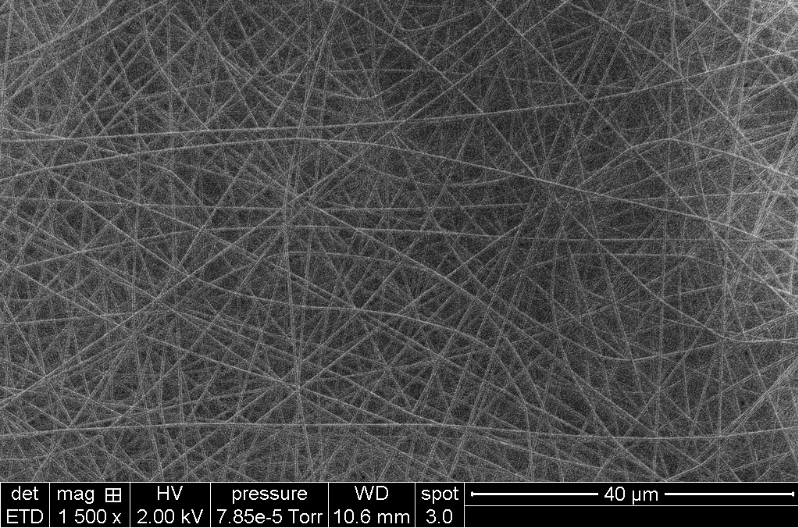

In the end, the students opted for a particular process: electrospinning. This technique uses an electric field to obtain extremely fine polymer filaments. Thin enough for electrostatic forces to appear. A bit like hair is attracted by an object that you rub on your sweater, the particles will be attracted and trapped on the surface of these filaments. It is therefore not necessary to have meshes the size of the particle to trap it, which makes electrospinning relevant for filtering fine particles such as viruses.

Polymer filaments made by students by electrospinning in the LMI laboratory - © Vincent Salles

A flexible and adaptable mask

Due to a lack of practical work, the class of 2019-2020 will be limited to design. But the project continues in 2020. Even if the health crisis continues, the constraints on teaching are partially lifted. Vincent Salles then turned to Edwin-Joffrey Courtial, CNRS research engineer on the 3d.FAB platform and lecturer in the M2 MAP 3D/2D course.

Attached to the Institute of Molecular and Supramolecular Chemistry and Biochemistry (ICBMS), this ISO 13485-certified technology platform is specialized in 3D printing. It has recently developed a new additive manufacturing process: Dynamic MoldingTM, which is now being developed by the start-up 3Deus Dynamics. This technique makes it possible to print complex shapes with fluid materials, which until now has been very difficult because "a fluid material will tend to collapse under its own weight," explains Edwin-Joffrey Courtial.

Hollow sphere in silicone elastomer obtained in 3D printing by Dynamic MoldingTM à 3d.FAB © Eric Le Roux

With his technical and scientific expertise, this engineer decided to propose this patented technology in a training approach.

Listening to Vincent Salles' idea, the mask project enters its realization phase. The students were trained in Dynamic MoldingTM and inserted the membrane obtained at the LMI into a flexible mask, adaptable to any facial physiology in order to improve comfort.

Design and manufacture of a flexible mask for the filtration of fine particles and viruses

A pedagogical innovation at the service of learning

This convergence of pedagogical and scientific skills has made it possible to respond to a concrete problem in line with the objectives of the M2 MAP3D/2D course. In particular, the preparation for the work-study program in a company, which is an integral part of the Master's program. The students tackled scientific aspects as well as notions of regulation, quality, medical standards, teamwork... all aspects to be considered in the industrial world.

The interest of this project also lies in its complementarity with the different areas of training. "The students had the opportunity to make a concrete link between the different teaching units of this course. This also shows the value of training through research," adds Eliane Espuche.

Born of a particular teaching context linked to the Covid-19 crisis, this project illustrates the strong link between training, research and the technological environment that exists at Claude Bernard Lyon 1 University by mobilizing students on a news topic.

"When students are more motivated, involved and interested in what they are doing, they learn much better and much more," says Vincent Salles.

This approach is visibly welcomed by the students of the two Master's classes:

"The fact that we are working on a current news topic like Covid-19 surely helped to create a form of synergy and a particular interest in the project, whereas this period was not easy for teachers and students." (Thomas).

"This project taught me that collaboration and team spirit are essential [...] and that the human side and openness are very important to complete a project successfully. This is [also] true in the working world" (Claire).

"We realize that we have accumulated skills since our last years of study, and that we are capable of mobilizing them on such a project" (Frédéric).

Class of 2020 - 2021 of the Master 2 MAP 3D/2D course

A project to be opened to other Masters of Lyon 1?

Given the good continuity established over the two classes of 2019 to 2020, the teachers are already considering the continuation of this project on other aspects: test of the mask's breathability and filtration of biological particles, virucidal treatment of the membrane, ... By integrating these different characterizations, this teaching of the M2 MAP3D/2D course could converge towards a real prototype of a usable medical mask.

However, several essential steps would still have to be validated, which would require the use of other scientific expertise developed at the university. For example, in biology for the testing of pathogenic particles.

The teaching team hopes to see the emergence of collaborations with other Masters programs at Claude Bernard Lyon 1 University, an approach that would give this course a unique cross-training character.

"From an organizational point of view, this would be quite innovative. As far as we know, there are few or no joint projects of this scale between Masters programs, especially in traditionally distant fields such as materials and biology," insist the project leaders.

To be continued with the 2021-2022 class of the MAP 3D/2D Master's degree!

About the Master MAP 3D/2D :

Learn more about this Master 2 course on the website of Master Chimie et sciences des matériaux

Laboratories and plateforms :

Laboratoire des Multimatériaux et Interfaces (LMI - Université Claude Bernard Lyon 1/CNRS)Institut de Chimie et de Biochimie Moléculaires et Supramoléculaires (ICBMS - Université Claude Bernard Lyon 1/CNRS/INSA Lyon/ CPE Lyon)

Plateforme 3DFAB

en

en fr

fr

es

es